HEEDS accelerates the product development process by automating analysis workflows, maximizing available computational hardware and software resources and efficiently exploring the design space for innovative solutions while assessing the new concepts to ensure performance requirements are met.

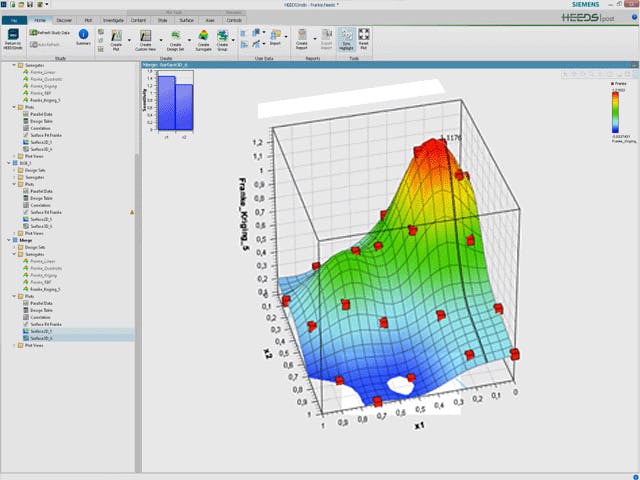

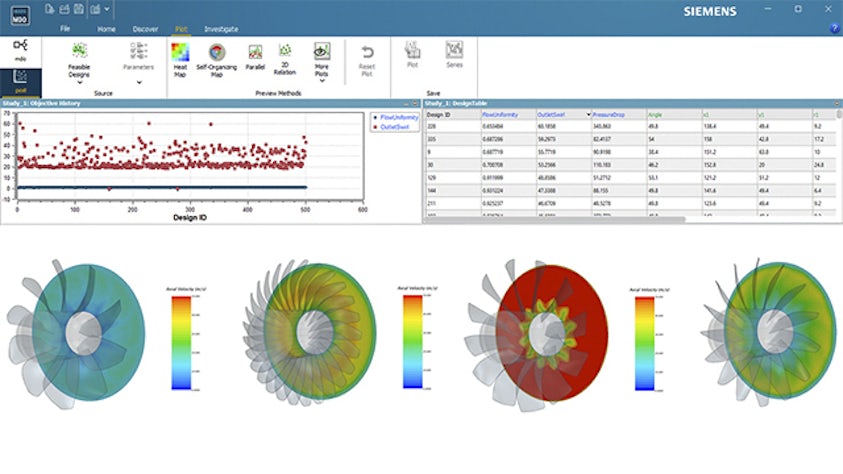

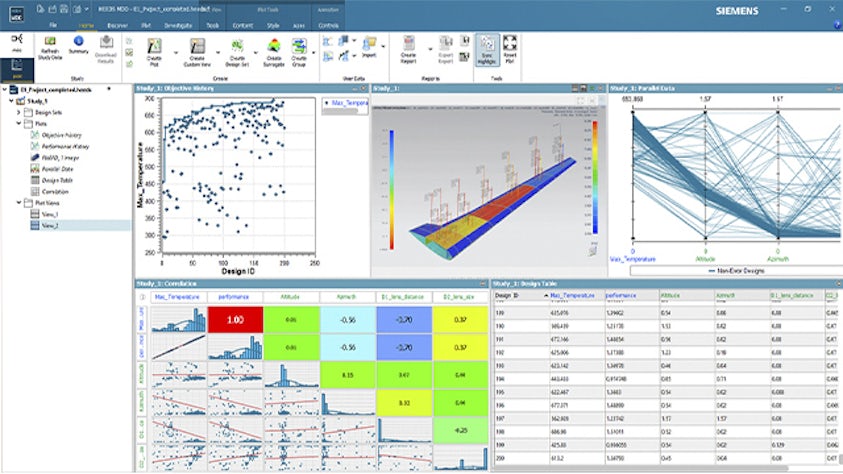

Design Space Exploration and Optimization

HEEDS enables users to explore a wide range of design options and parameters, facilitating the discovery of optimized solutions to complex engineering problems.

Time and Cost Efficiency

By automating the design process and leveraging optimization algorithms, HEEDS helps reduce the time and cost associated with product development through rapid analysis of numerous design variations.

Multi-disciplinary Optimization

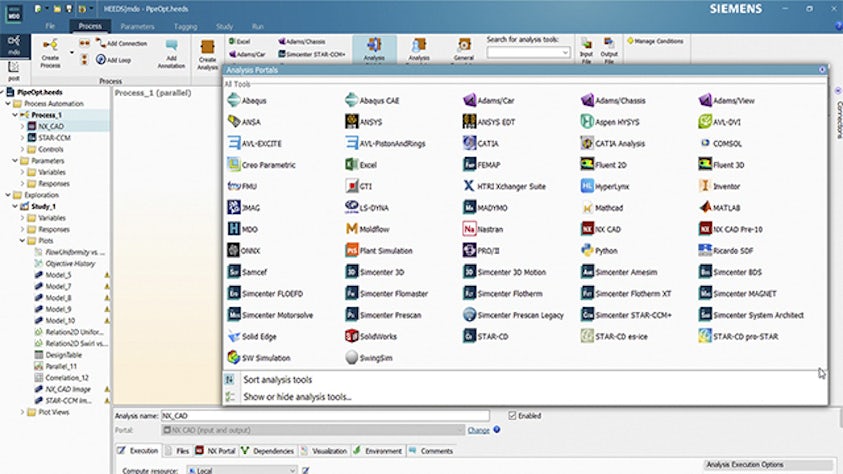

HEEDS supports the consideration of multiple engineering disciplines simultaneously, allowing for a holistic approach to design optimization that considers interactions between different domains.

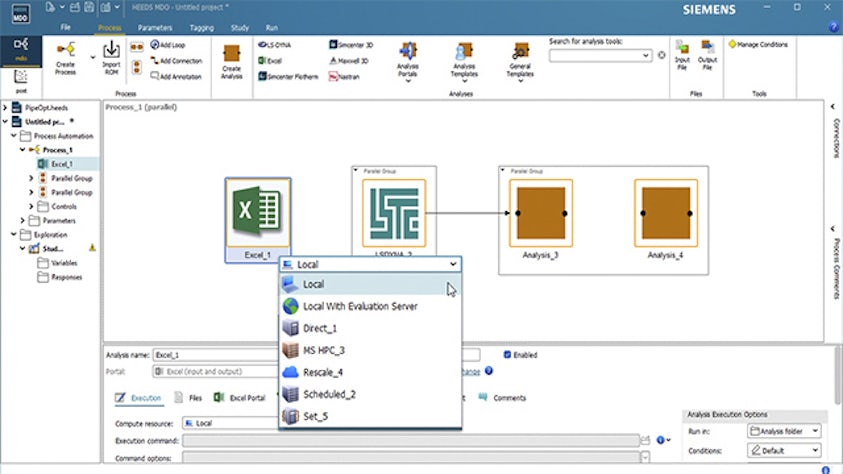

Workflow Automation

HEEDS automates repetitive tasks in the design and optimization process, streamlining workflows and enhancing efficiency. This automation can lead to faster decision-making and more comprehensive exploration of design spaces.

What's new in HEEDS 2310?

Uncover how the new functionalities in HEEDS 2310, such as a new novel AI integration, data import enhancements, and refined portal version management will lead you to discover better designs, even faster!