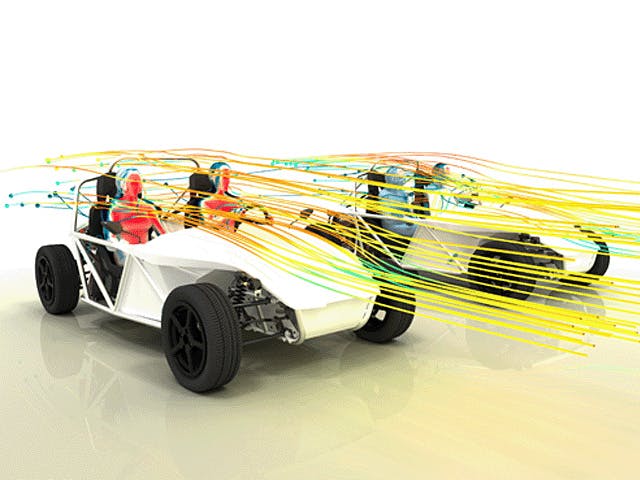

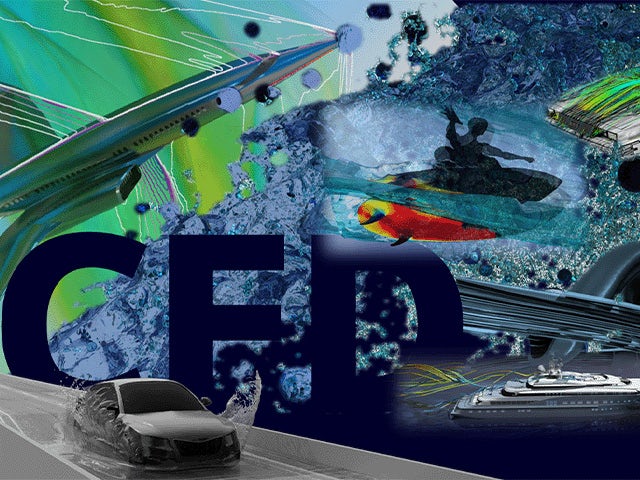

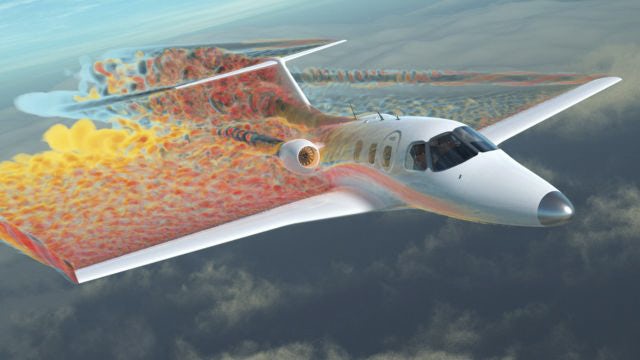

Simcenter STAR-CCM+ is a multiphysics CFD software that enables CFD engineers to model the complexity and explore the possibilities of products operating under real-world conditions.

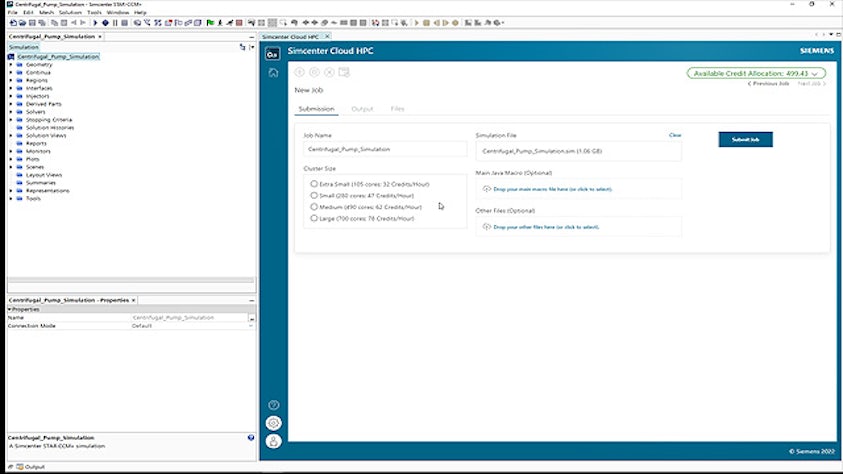

Boost your productivity with a fully integrated user interface

Find everything in this single unified software. Simcenter STAR-CCM+ includes pre-processing via meshing through multiphysics modeling, data analysis and photorealistic visualization and VR.

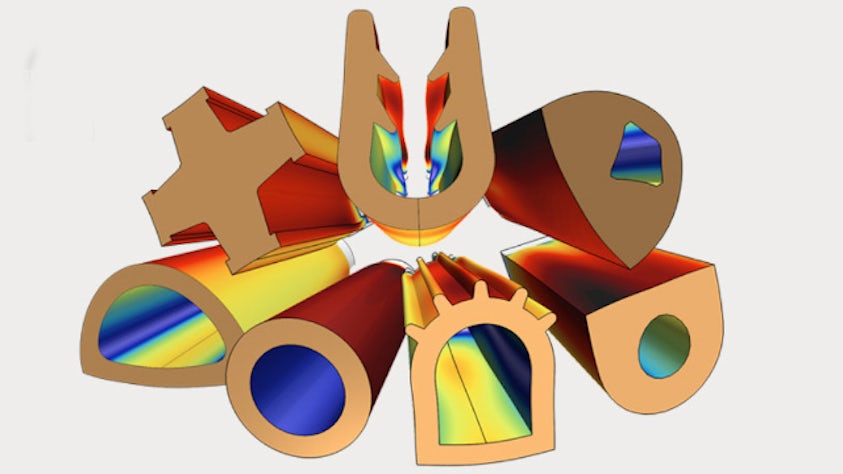

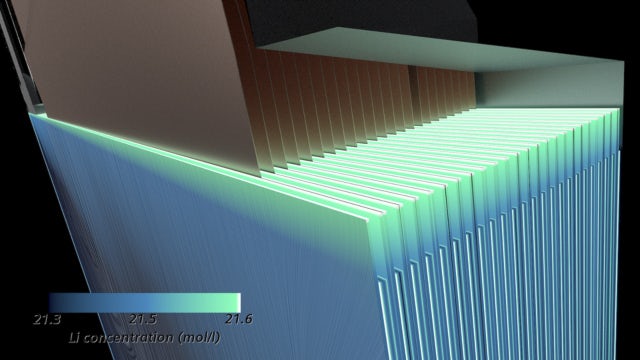

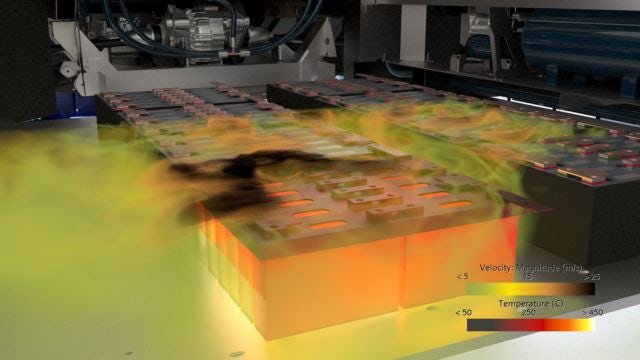

Cope with the most complex applications

Cover physics way beyond fluid flow and heat transfer. This fully integrated solver platform allows you to run even the most complex multiphysics CFD simulations.

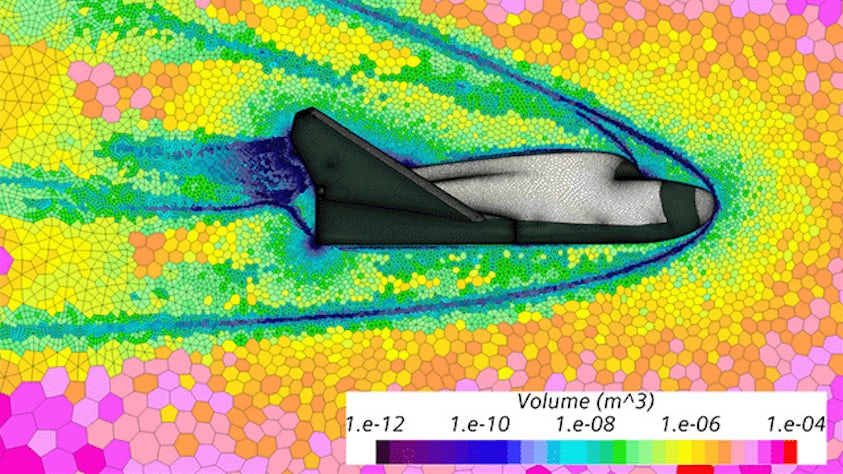

Cut CFD preparation times

Reduce simulation preparation time from a week to hours with automated meshing and pre-processing of complex geometries. With cutting-edge technologies like automated computer-aided design (CAD) cleanup, surface wrapping and automated high-fidelity meshing, spend your time doing what matters: engineering better products.

Leverage powerful end-to-end, code-free workflow automation and fully embedded design exploration

Leverage CFD-based design exploration with automated simulations from start to finish.

What's new?

- Leverage integrated SPH technology

- Go faster with more GPU hardware options

- Run faster, more accurate turbomachinery CFD

- Model the complexity of strongly coupled fluid-structure interaction

- And much more